- HOME/

- About Stanley/

- Stanley's 100th Anniversary Site

Stanley's 100th Anniversary Site

Rapid Growth after Recovery

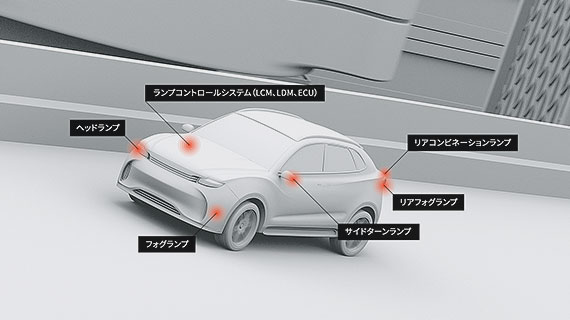

In 1947, Stanley Electric's traditional light bulb products were revived by only 12 of its employees in a 100㎡ building that avoided damage from the war. In August of the same year, the company started to manufacture selenium rectifiers and enamel resistors again. Afterwards, the metal-back sealed beams that the company launched in April 1957 quickly gained popularity in the market as the automotive industry was booming with high economic growth. In the 1950s, the company enjoyed rapid success including hot-selling electronic products, particularly with selenium photocell light meters, which were recognized as innovative products. In December 1960, the Hatano Factory opened, which currently serves the company's central manufacturing function. In February 1962, the company made its debut on the Tokyo Stock Exchange by being listed on its First Section.

Download the Chapter 2 PDFCHRONOLOGY

Relaunched Kitano Denki Kogyo Co., Ltd.

Started to manufacture and sell electric ranges and electric "kotatsu" heater-tables

Resumed the manufacturing of selenium rectifier plates

Launched portable water heaters for bathtubs

Announced the Stanley's Four Values

Launched electric fermenters

Resumed the manufacturing of light bulbs

Rechargeable lamps released in response to frequent electrical outages

Resumed exports

Launched voltage regulators and electric experimental equipment

Developed power supply equipment for offices

Changed the company name back to Stanley Electric Co., Ltd.

The Restoration of Stanley Electric

When World War II ended, Stanley Electric was dissolved. In October 1945, in response to earnest calls for the company's restoration from former employees, Stanley Electric held a relaunch ceremony at Shunpuryo dormitory in Nakameguro and started to restore the company. Later, on November 1, 1949, the company's name, Stanley Electric, was finally reinstated and the Meguro Factory was renovated to resume exporting of automotive light bulbs.

While manufacturing household electric heaters, the Todoroki Factory started to produce selenium rectifiers, enamel resistors, and other products. These rectifiers were new products aimed at the fields of broadcasting and telecommunication. Also, the company entered into the field of power supply equipment and opened up sales channels to telecommunication and electrical equipment manufacturers to establish firm foundations for the electronic equipment business as well as for the automotive light bulb business.

Developed power supply equipment for broadcasting equipment

Caravans (visiting customers by car) started

Started to manufacture sealed beams and automotive lighting devices

Launched glass reflective sealed beams (type that can be disassembled)

Started to distribute silicon resistors

Developed rectifier transformers

Acquired the JIS license for small light bulbs

Launched enclosed wire wound resistors

Launched the Ever Shine sealed beam with improved reflective surface and replaceable bulbs

Started to promote sales to Honda and then received the first order for 500 pieces of automotive light bulbs

Installed vacuum deposition equipment for selenium rectifier plates at the Todoroki Factory

Started the mass production development of selenium photocells

Entry into the Photoelectric Field

In the mid-1950s, Stanley Electric made great progress not only in automotive products but also in photoelectric products such as photocells and light meters. In 1955, the company began to develop selenium photocells by utilizing the technologies it developed for selenium rectifier plates. In the following year of 1956, it developed blue selenium photocells that were superior to products from overseas manufacturers. This became widely known among light meter manufacturers, resulting in a large number of business inquiries to the company.

In 1959, a fully automatic light meter that Stanley Electric developed in collaboration with Yashica Company, Ltd. attracted the industry's attention, and later ignited an electric eye (EE) boom in the camera industry.

The company's photocell products represented one of the most advanced technologies at the time, and their development was led by President Takaharu Kitano, who closely worked with his employees, sharing challenges as well as joy throughout the product development.

Acquired the JIS license for enamel resistors

Increased capital stock to 40,000,000 JPY

Launched neutral gear indicator (the first electrical parts for Honda)

Launched fully-sealed metal-back sealed beams

Launched auto lighters

Launched light bulbs for the Honda Dream and Benly

Metal-back Sealed Beams--Foundation for the Company's Growth

Japan's automotive industry rapidly grew with high economic growth, and car production volume saw a significant rise. Stanley Electric's future depended on its ability to ride one this booming trend. Thus, the company made a crucial decision to develop metal-back sealed beams in place of all-glass sealed beams. The metal-back sealed beams were a new type of dual-gas fully-sealed beam. After overcoming formidable challenges, the company was finally successful in offering the same level of performance as all-glass sealed beams with 30% fewer costs. In addition, the metal-back sealed beams were made available in unconventional forms such as rectangular and horseshoe shapes. The company's original metal-back sealed beam therefore quickly gained popularity in the market, building a foundation for the company's continuous growth in the automotive industry.

Launched first-in-Japan four-lamp metal-back sealed beams

Started over-the-counter dealings of stocks on the Tokyo Stock Exchange

Launched rectangular metal-back sealed beams

Launched mercury lamps and its stabilizers for street lights

Developed photocell light meters for photographs

Beauty LM EE camera adopted Stanley light meters using selenium photocells

Completed dual-gas fully-sealed metal-back sealed beams

New Yashica III eight-millimeter movie camera adopted exposure aperture light meters

Received an order for headlamps for the Honda Super Cub

Increased capital stock to 120,000,000 JPY

Completed the first-in-Japan transistor PBX phone system

Launched the in-house newsletter Stanley Shimbun

Increased capital stock to 550,000,000 JPY

Listed on the Second Section of the Tokyo Stock Exchange

Listed on the First Section of the Tokyo Stock Exchange

Relaunched Kitano Denki Kogyo Co., Ltd.

Started to manufacture and sell electric ranges and electric "kotatsu" heater-tables

Resumed the manufacturing of selenium rectifier plates

Launched portable water heaters for bathtubs

Announced the Stanley's Four Values

Launched electric fermenters

Resumed the manufacturing of light bulbs

Rechargeable lamps released in response to frequent electrical outages

Resumed exports

Launched voltage regulators and electric experimental equipment

Developed power supply equipment for offices

Changed the company name back to Stanley Electric Co., Ltd.

The Restoration of Stanley Electric

When World War II ended, Stanley Electric was dissolved. In October 1945, in response to earnest calls for the company's restoration from former employees, Stanley Electric held a relaunch ceremony at Shunpuryo dormitory in Nakameguro and started to restore the company. Later, on November 1, 1949, the company's name, Stanley Electric, was finally reinstated and the Meguro Factory was renovated to resume exporting of automotive light bulbs.

While manufacturing household electric heaters, the Todoroki Factory started to produce selenium rectifiers, enamel resistors, and other products. These rectifiers were new products aimed at the fields of broadcasting and telecommunication. Also, the company entered into the field of power supply equipment and opened up sales channels to telecommunication and electrical equipment manufacturers to establish firm foundations for the electronic equipment business as well as for the automotive light bulb business.

The company renamed as Stanley Electric again

Developed power supply equipment for broadcasting equipment

Caravans (visiting customers by car) started

Started to manufacture sealed beams and automotive lighting devices

Launched glass reflective sealed beams (type that can be disassembled)

Started to distribute silicon resistors

Developed rectifier transformers

Acquired the JIS license for small light bulbs

Launched enclosed wire wound resistors

Launched the Ever Shine sealed beam with improved reflective surface and replaceable bulbs

Started to promote sales to Honda and then received the first order for 500 pieces of automotive light bulbs

Installed vacuum deposition equipment for selenium rectifier plates at the Todoroki Factory

Started the mass production development of selenium photocells

Entry into the Photoelectric Field

In the mid-1950s, Stanley Electric made great progress not only in automotive products but also in photoelectric products such as photocells and light meters. In 1955, the company began to develop selenium photocells by utilizing the technologies it developed for selenium rectifier plates. In the following year of 1956, it developed blue selenium photocells that were superior to products from overseas manufacturers. This became widely known among light meter manufacturers, resulting in a large number of business inquiries to the company.

In 1959, a fully automatic light meter that Stanley Electric developed in collaboration with Yashica Company, Ltd. attracted the industry's attention, and later ignited an electric eye (EE) boom in the camera industry.

The company's photocell products represented one of the most advanced technologies at the time, and their development was led by President Takaharu Kitano, who closely worked with his employees, sharing challenges as well as joy throughout the product development.

Acquired the JIS license for enamel resistors

Increased capital stock to 40,000,000 JPY

Launched neutral gear indicator (the first electrical parts for Honda)

Launched fully-sealed metal-back sealed beams

Metal-back Sealed Beams--Foundation for the Company's Growth

Japan's automotive industry rapidly grew with high economic growth, and car production volume saw a significant rise. Stanley Electric's future depended on its ability to ride one this booming trend. Thus, the company made a crucial decision to develop metal-back sealed beams in place of all-glass sealed beams. The metal-back sealed beams were a new type of dual-gas fully-sealed beam. After overcoming formidable challenges, the company was finally successful in offering the same level of performance as all-glass sealed beams with 30% fewer costs. In addition, the metal-back sealed beams were made available in unconventional forms such as rectangular and horseshoe shapes. The company's original metal-back sealed beam therefore quickly gained popularity in the market, building a foundation for the company's continuous growth in the automotive industry.

Fully-sealed Metal-back sealed beam

Launched auto lighters

Launched light bulbs for the Honda Dream and Benly

Launched first-in-Japan four-lamp metal-back sealed beams

Started over-the-counter dealings of stocks on the Tokyo Stock Exchange始

Launched rectangular metal-back sealed beams

Launched mercury lamps and its stabilizers for street lights

Developed photocell light meters for photographs

Beauty LM EE camera adopted Stanley light meters using selenium photocells

Completed dual-gas fully-sealed metal-back sealed beams

New Yashica III eight-millimeter movie camera adopted exposure aperture light meters

Received an order for headlamps for the Honda Super Cub

Increased capital stock to 120,000,000 JPY

Completed the first-in-Japan transistor PBX phone system

Opened the Hamamatsu Factory

Opened the Hatano Factory

Launched the in-house newsletter Stanley Shimbun

Increased capital stock to 550,000,000 JPY

Listed on the Second Section of the Tokyo Stock Exchange

Listed on the First Section of the Tokyo Stock Exchange