"Reducing nighttime traffic accidents by producing high-resolution light with an ADB system using liquid crystal devices."

When driving at night, drivers are recommended to use their high beams during normal driving so that they can see pedestrians and the shape of the road in the distance. In actual traffic environments, however, they need to use different lights depending on the situation, or the glare may lead to dangerous situations. To address this, we have developed a function called ADB (adaptive driving beams) to provide safe and secure visibility while driving. Using an in-vehicle camera, ADB detects oncoming and preceding vehicles and automatically extinguishes part of the high-beam flux distribution so that glare does not interfere with the vision of the other drivers. This is also known as glare-free high beams.

A system that uses liquid crystal devices (LCD) with this ADB function is called an LCD-ADB. As a result, it can contribute to reducing nighttime accidents, especially those involving pedestrian crossing.

Also, in order to install ADB in many vehicles, it will be necessary to reduce the cost. We believe that LCD-ADB has the potential to realize ADB with higher resolution at the same cost.

Key technology

"This is achieved by taking advantage of the technological and development capabilities of the ADB System

LCD Panel Business, which uses LCD that allow you to set the shading range arbitrarily to "

shutters.

Offering solutions that other headlight manufacturers cannot

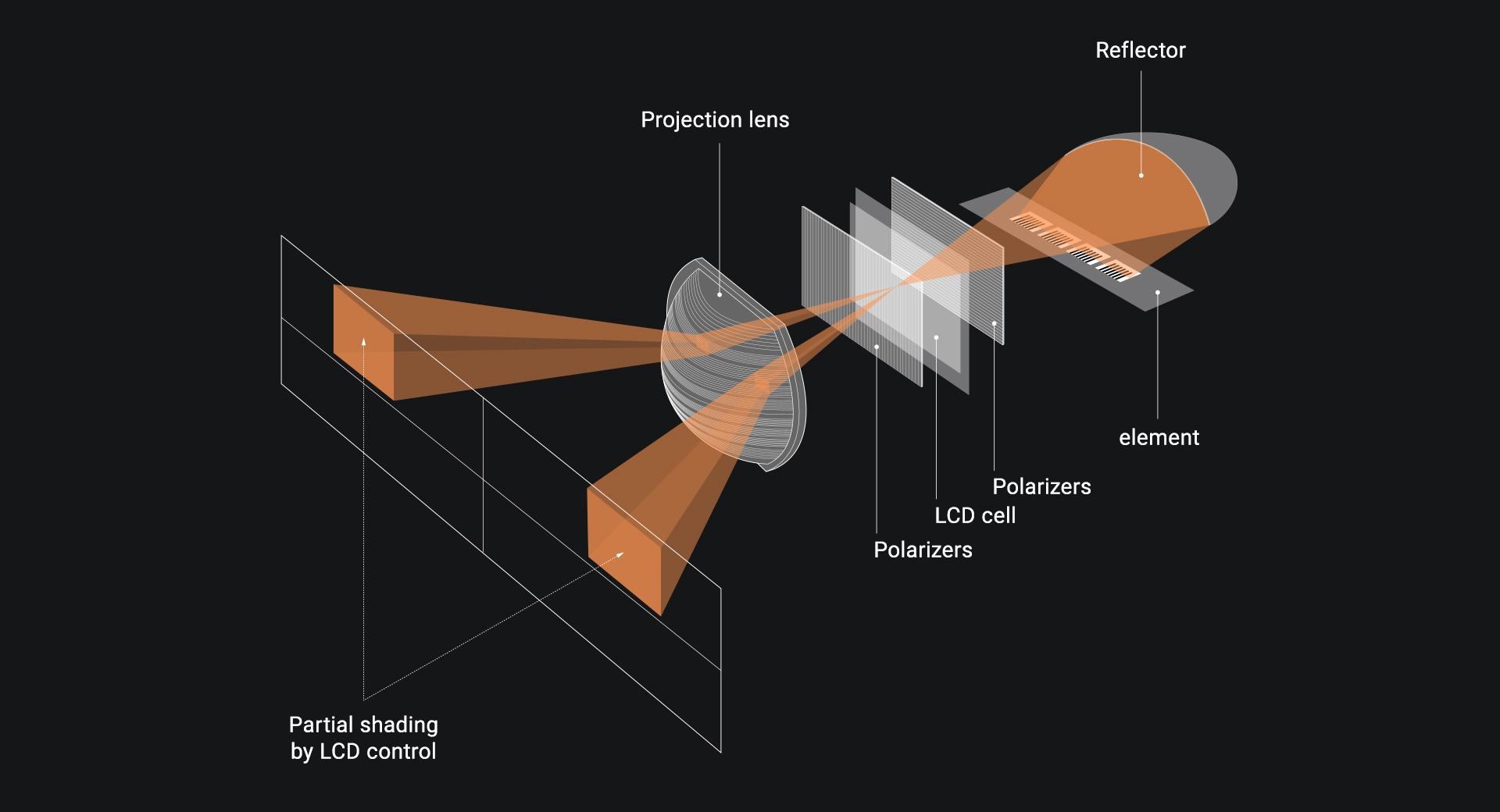

The LCD-ADB system mechanism starts by creating a normal high-beam light distribution. The system prevents glare by placing an LCD in the light path, turning on the LCD for the entire area when using it as a high beam, and turning off the LCD for a certain position when a preceding or an oncoming vehicle arrives.

The shading range can be set arbitrarily by dividing the LCD, using divided positioning based on accident analysis. It also takes into account pedestrians and signboard glare, and the in-vehicle camera detects pedestrians and controls the brightness at face level to avoid glare.

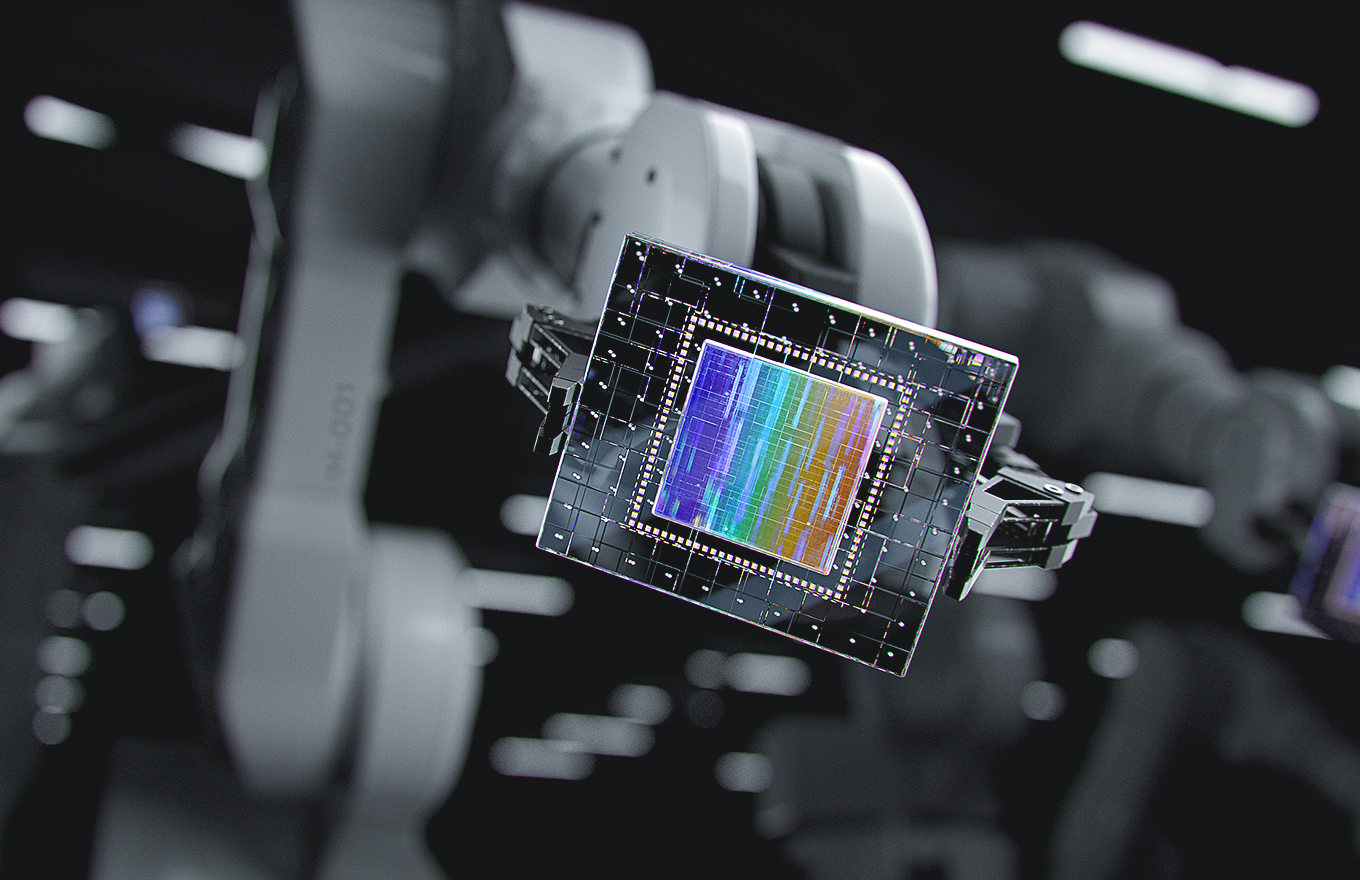

Lamp unit: An ADB unit composed of an LED light source, an LCD, and a projection lens

For the shading mechanism, the unit has two slit-like structural components called polarizers, which allow light to pass in a specific direction, and an LCD is placed between them. For the internal and external polarizers, it has polarizers with sideways slits on the light source side, an LCD in the center, and polarizers with slits rotated 90° on the outside. Only the polarizers block light; the LCD itself does not. First, only the horizontal light passes behind the LCD, and when there is no voltage applied to the LCD--in other words, when the LCD is turned off--then the horizontal light is caught by the vertical slit in front of the LCD when it passes. That means that the light is not output. In contrast, when voltage is applied and the LCD is turned on, it functions to rotate the light passing through the horizontal slit 90° from horizontal to vertical. Then, once the light rotates from horizontal to vertical, it can pass through the vertical slit in the front.

Our LCD panel business allows us to leverage our technological, development, and production capabilities to create LCDs for headlights, so we can create value by offering solutions that other manufacturers cannot.

Difficult, time-consuming challenges

Optical loss due to polarizers

LCD characteristics at low temperatures

One challenge was optical loss due to the use of polarized light, which is a fundamental characteristic of LCDs. If you use LCDs in a simple application--for example, LCD TVs--you may not be able to remove half of the light. This is because only the light with the same wave direction as that of the slit of the polarizer passes through the unpolarized light (light with a mixture of different polarization states), and the remaining light is absorbed or reflected. Given this, by using a reflector to reflect the light that could not pass through the polarizer and rotating the wave direction by 90° so that it is in the same direction as the slit and then returning it, we constructed an optical system that recycles light so that the light that could not pass through the polarizer at first can do so later, thereby preventing optical loss.

Also, the liquid crystal materials that make up LCDs tend to become viscous and slow-moving at low temperatures of -30°C or below. This means that it takes time for the light to come on, even if the driver flips the light switch to turn on the low beams when they get in. If this takes more than ten seconds, then it may not be possible to ensure safe visibility, even if the driver wants to check what lies ahead in the dark. Because this system does not satisfy the safety function as an important safety component, we developed an LCD equipped with a heater function that can warm the LCD itself in a short time, thereby solving the problem of slow operation at low temperatures.

Approach

Popularize high-performance ADB systems

that can be installed in all vehicles

The ADB had fewer divisions in the early stages of its development, and then it shifted to a series of a few thousand LEDs for higher resolution. However, in terms of both cost and technology, we believe that an ADB system using such an LCD would be the best choice for installing the safer, high-resolution ADB in all vehicles.

We are using Stanley's LCD business technologies to overcome various challenges in using LCDs in headlights. We will also work to develop and popularize an ADB system that is safer and can help reduce accidents.

Technology