Realizing a society free from traffic accidents with headlamps that offer the same visibility at night as during the day

In the average year, many fatal traffic accidents occur at night. There are many dangers accompanying night-time driving. The risks of delays in noticing pedestrians and of colliding with structures at night are much higher than during the day. In these situations, the reduction of "blind spots" will be important to allow drivers to drive safely. With our headlamp system that offers excellent light distribution control functions, Stanley strives to ensure driving visibility at night that is even better than daytime driving, with the aim of achieving zero night-time traffic accidents in the future.

Key Technology

Excellent Light Distribution Control

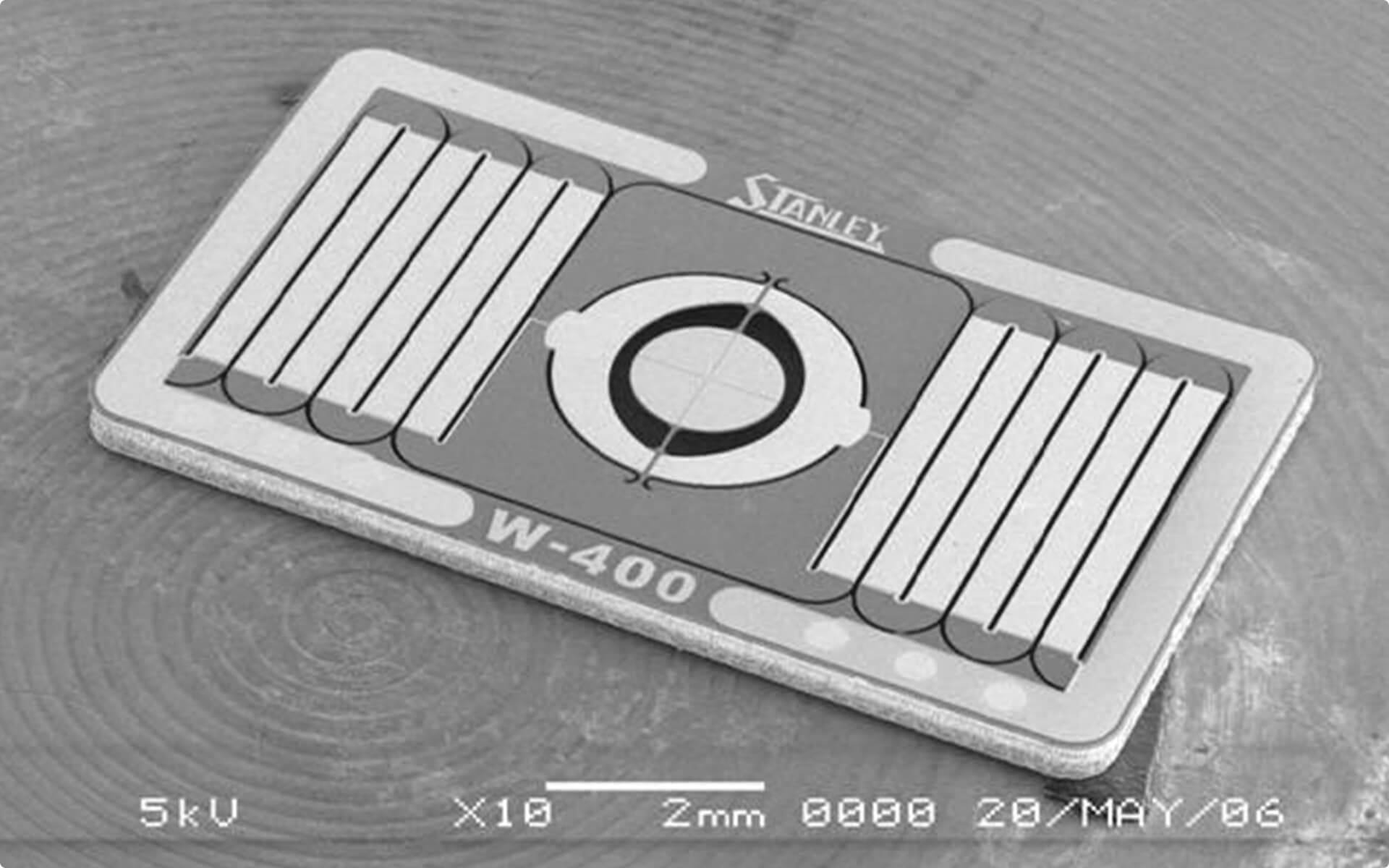

2D-MEMS Scanning Mirror Device

High-speed scanning of the laser rays creates "planes" of light, rather than "points." Increasing the number of light-blocking segments achieves headlamps with excellent light distribution control.

Blue laser light is reflected with MEMS (Micro-Electro-Mechanical

System) mirror and converted into white light with phosphor. The angle

of the mirror can be controlled both horizontally and vertically,

allowing for free light distribution formation. The laser beam shone

onto the mirror is scanned at high speed to create a "plane" for

formation of light distribution in various shapes. Stanley have

continued to refine the design of the optical lens and the MEMS mirror

angle control, enabling us to emit stronger light.

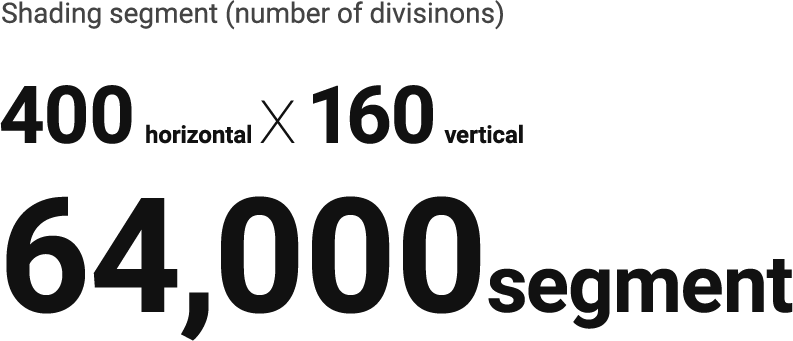

The number of segments that can control brightness has been increased

from the current 12 segments to 64,000 segments in a 400 (horizontal) x

160 (vertical) grid, making it possible to control irradiation in very

small area. By smoothly shielding a part of the high beam to match the

behavior of oncoming vehicles, cars up ahead, and pedestrians, the

driver can ensure visibility without blinding others in the vicinity. In

addition, when driving at high speeds, by reducing the scanning area of

the MEMS mirror and making bright "planes" of light, drivers can ensure

visibility of longer distances.

By providing appropriate light distribution to match driving speed with

a combination of lasers and the 2D-MEMS Scanning Mirror Device, Stanley

is assisting drivers to drive safely at night.

Challenge

Realizing high-precision light and improving efficiency

The realization of light distribution of high precision will require manufacturing technology of higher standards. For example, to take maximum advantage of laser beams, optical technologies such as optical lenses and reflectors, as well as mechanical technologies such as technology for adjusting the lasers as designed, are essential.

Another requirement is opto-mechatronics technology, in which laser activation control for accurate switching of the laser on and off is combined in optimal ways with electronics technology for MEMS mirror angle control. Stanley believe that raising the standards of each of these technologies will help us to realize the ultimate in light distribution.

MEMS Scanner Device (Mirror with 1.2 mm diameter)

Approach

Taking scanning of light into the next domain

Making it easier to detect reflective objects and hazards on the road

and the condition of the road condition.

Also enabling more

accurate measurement of the distance between cars.

In addition to using MEMS mirror devices as a display by scanning light similarly to headlamps, Stanley are also considering rolling out a range of applications for sensing purposes by receiving light, and as an actuator by moving the MEMS mirror device. In this way, we will apply and extend the technology we have built up in the course of development and move into other domains.

Technology