- HOME /

- Product information /

- UV-C products /

- How UV-C works in our daily lives /

- Water disinfection with UV-C technology

Water disinfection with UV-C technology

Offering safe water

to the world

It is said that there are only nine countries in the world where tap water can be drank straight from the faucet. UV-C disinfection is expected to increase in use in the near future as a technology that can deliver safe and secure water to everyone in the world.

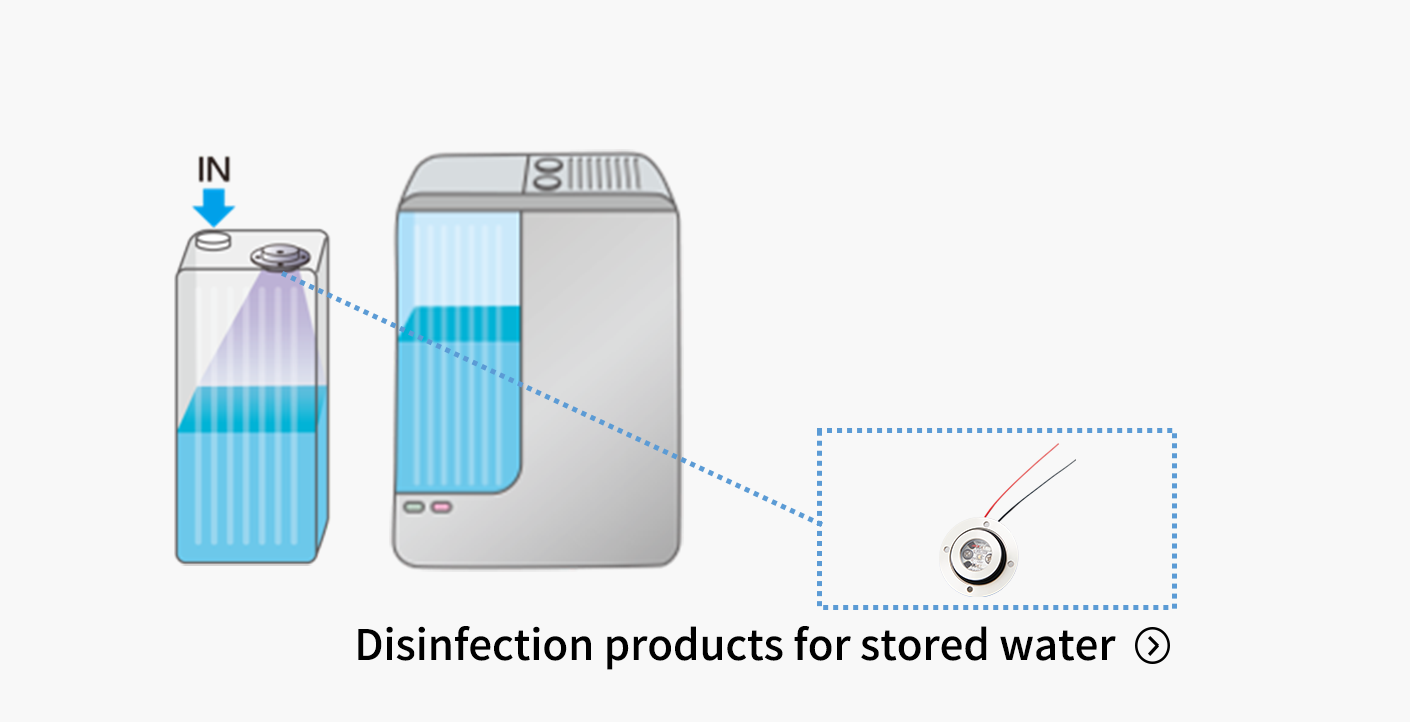

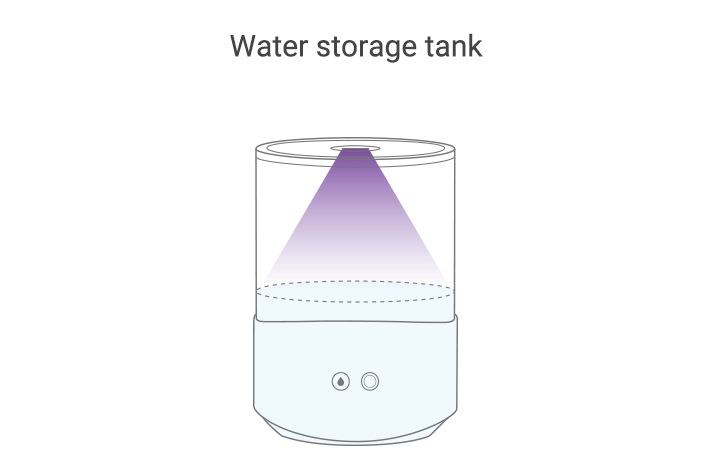

Water storage type

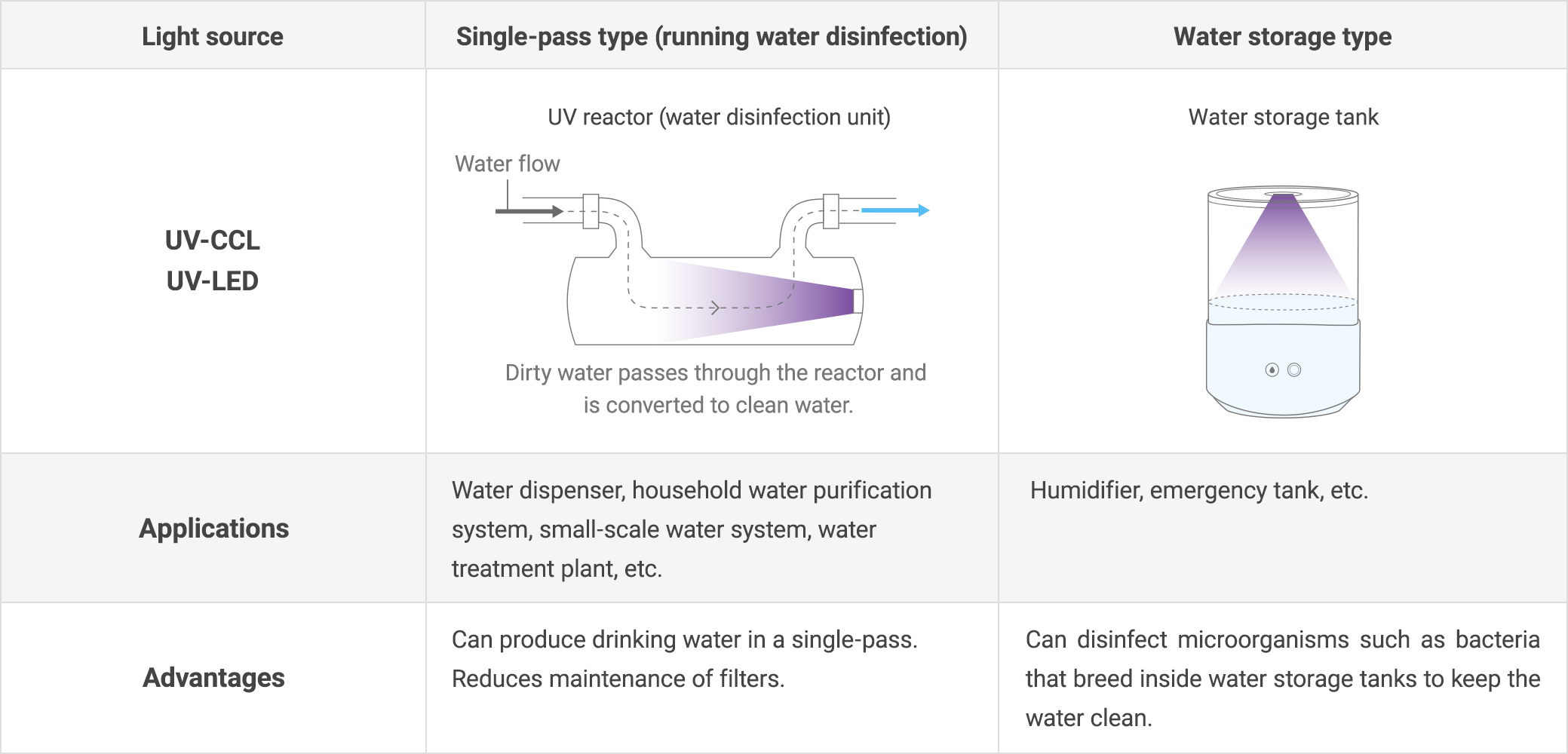

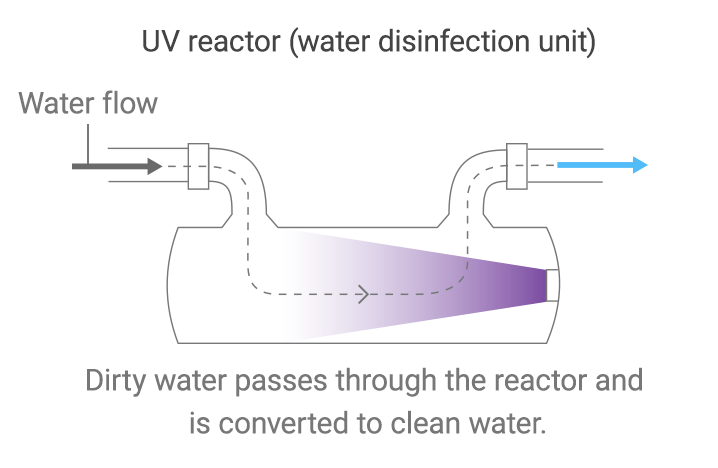

Basic structure of water disinfection

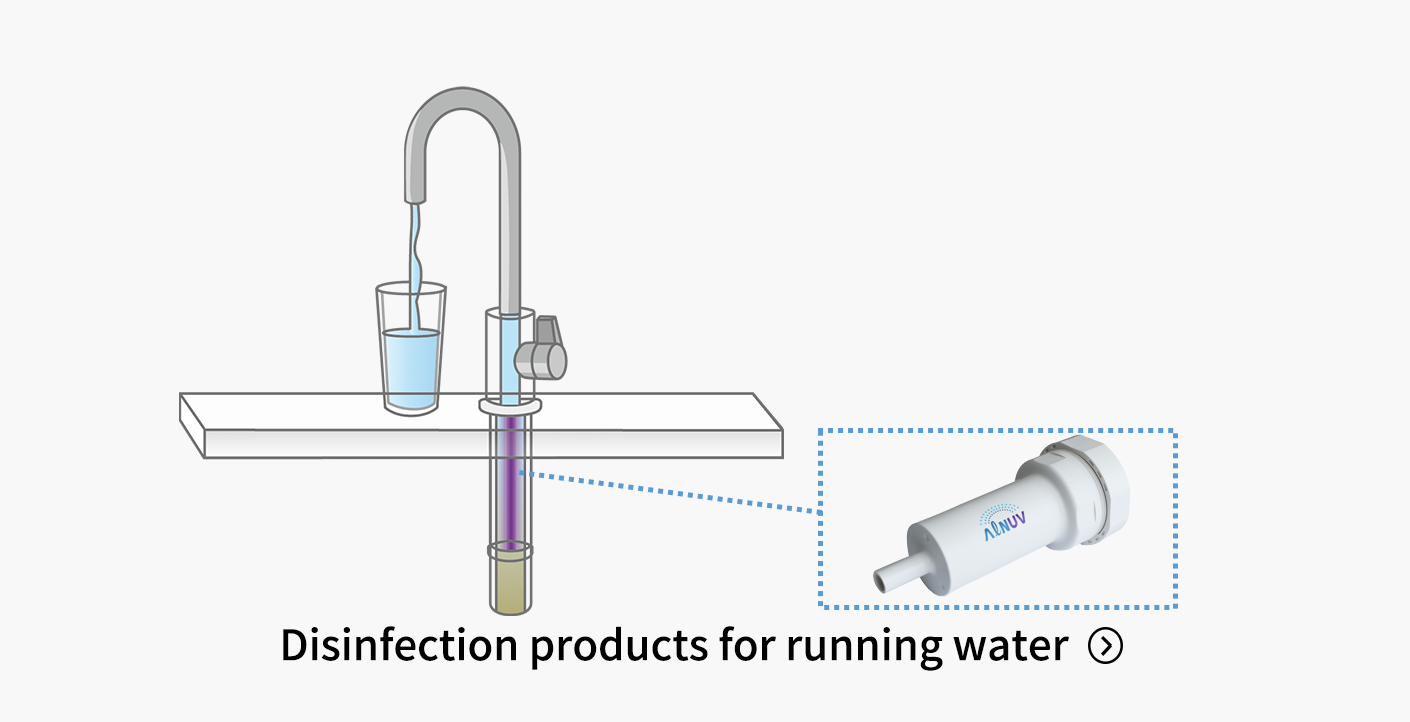

There are two types of water disinfection; a single-pass type that irradiates ultraviolet to disinfect running water such as a household water purification system, and a water storage type that irradiates and disinfects water inside a water storage tank such as a humidifier.

| Light source | Single-pass type (running water disinfection) | Water storage type |

|---|---|---|

| UV-CCL UV-LED |

|

|

| Applications | Water dispenser, household water purification system, small-scale water system, water treatment plant, etc. | Humidifier, emergency tank, etc. |

| Advantages | Can produce drinking water in a single-pass. Reduces maintenance of filters. | Can disinfect microorganisms such as bacteria that breed inside water storage tanks to keep the water clean. |

Click for the image.

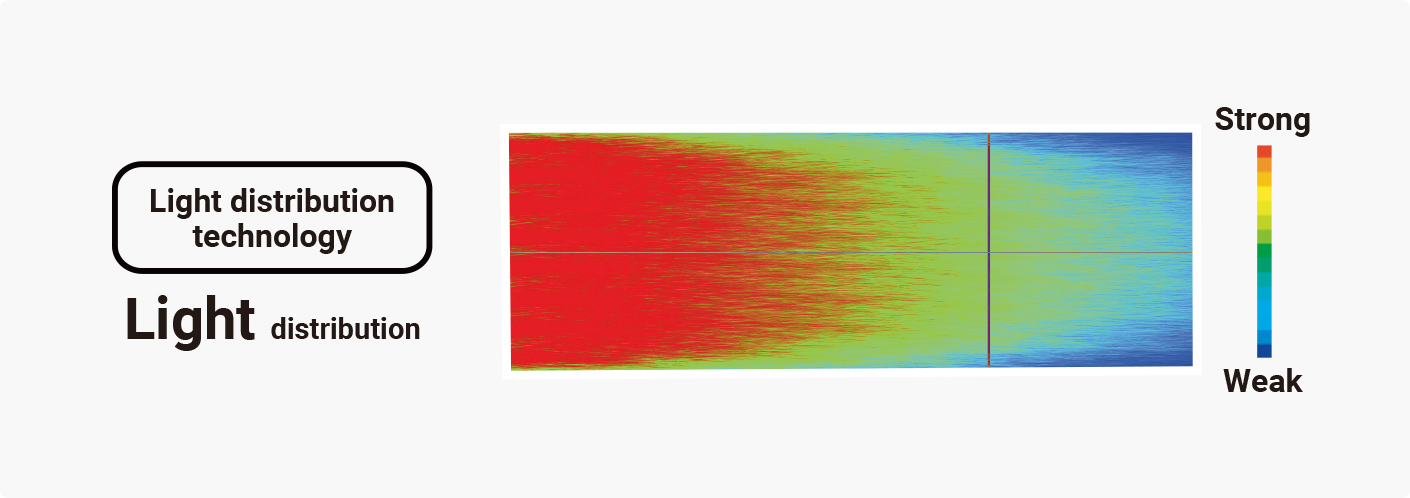

Irradiation simulation

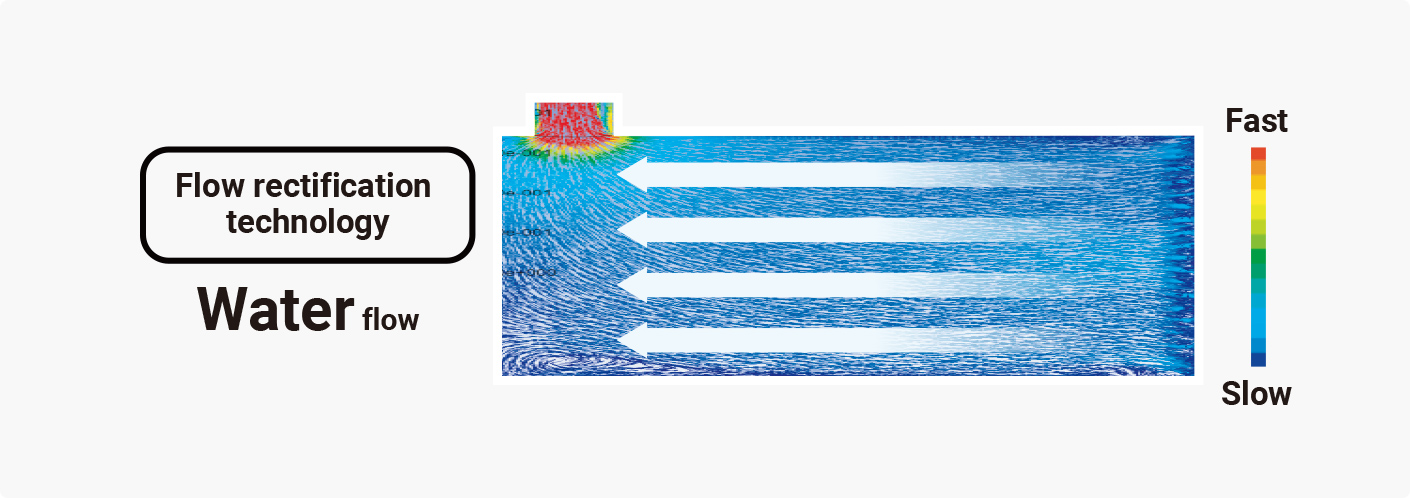

Stanley Electric simulates reactor's disinfection to optimize its efficiency (the size, light source type and quantity, etc.) and rectify the reactor's water flow inside, based on the customer's running water conditions.

We also offers optimized disinfection driving conditions to prolong the life of the reactor and to save energy.

Achieving a uniform flow rate that

reduces water speed using a flow rectification mechanism

Water flow has been rectified. (Vector direction and color)

Click for the image.

Disinfection effect

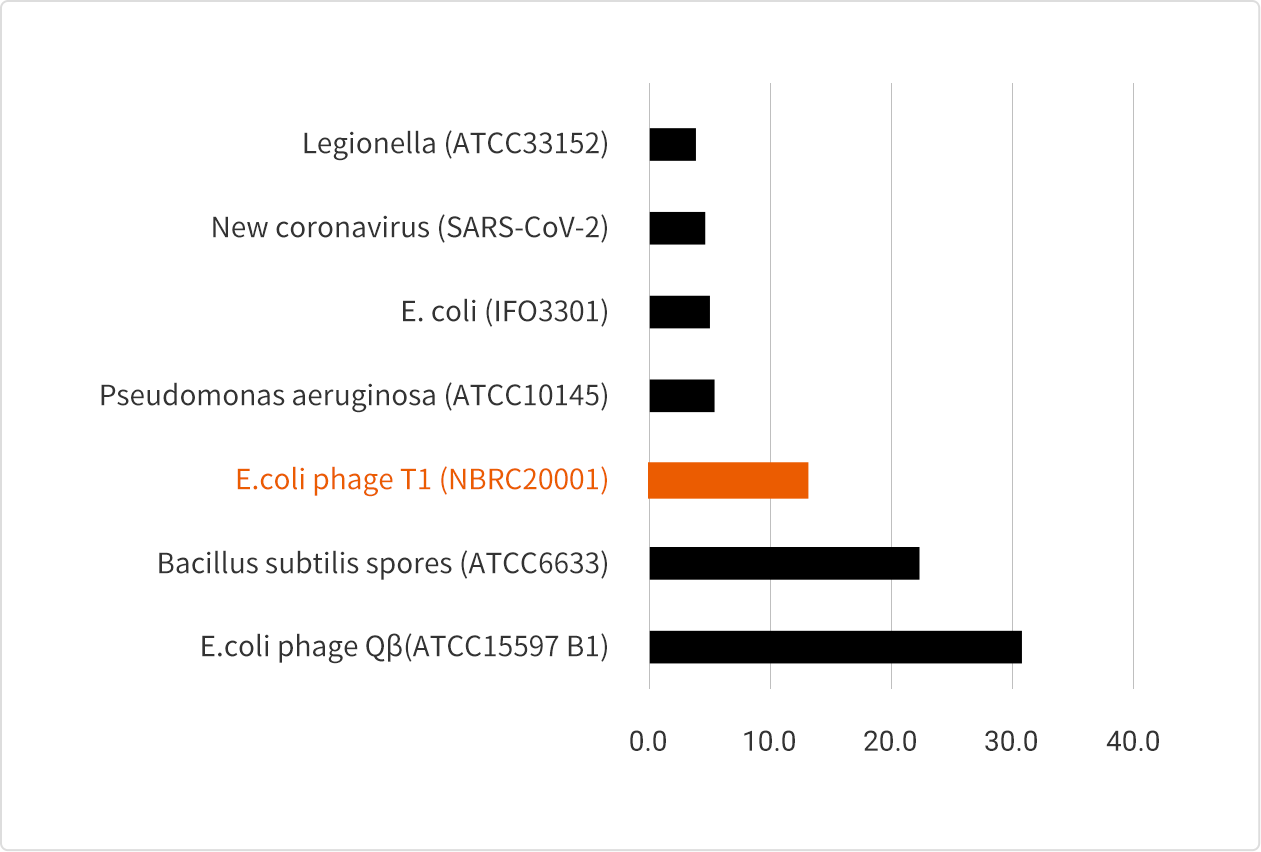

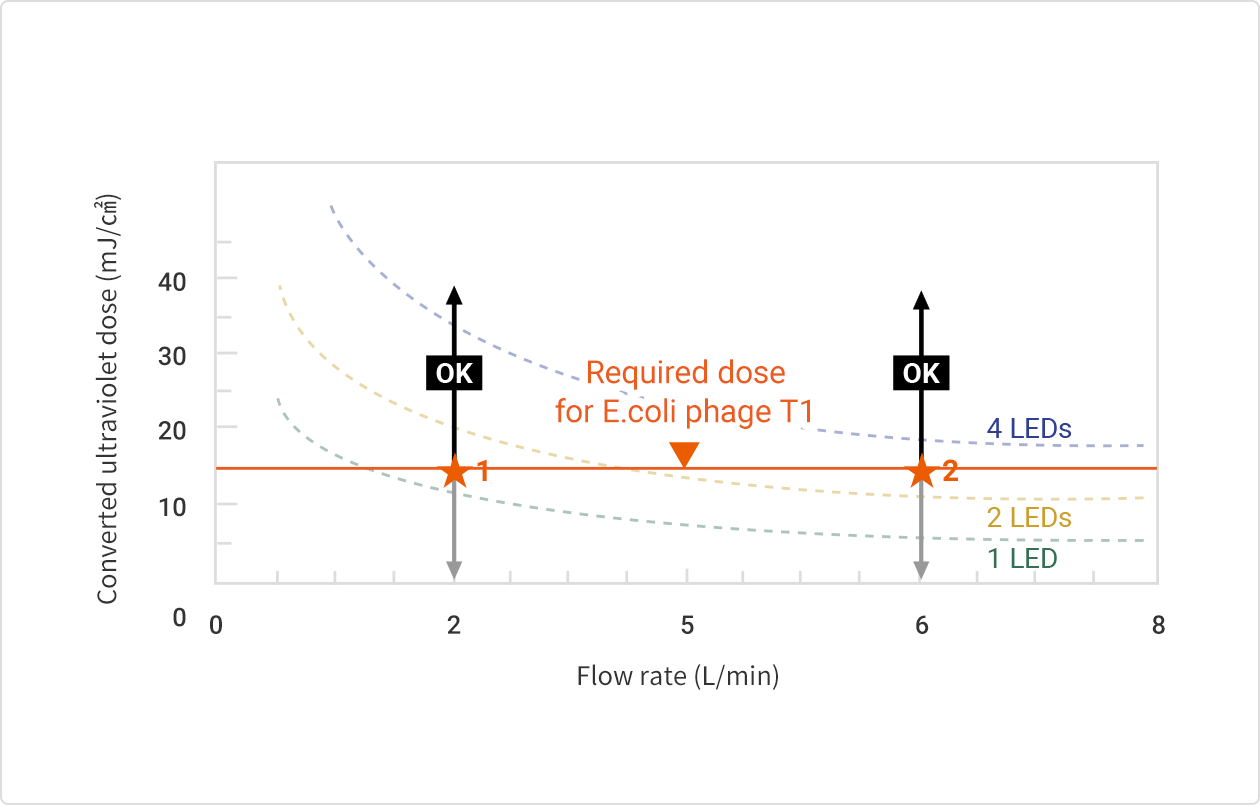

The required dose varies depending on the type of bacteria and virus to be disinfected. To disinfect 99.9% of E.coli phage T1, the required dose is 12.9 mJ/㎠ (based on test results at Stanley Electric).

Click for the image.

The greater the flow rate, the more light sources (LEDs) are required inside the reactor. For a flow rate of 2 liters, the required dose of 12.9 mJ/ can be obtained as long as the reactor has two or more LEDs (★1). For a flow rate of 6 liters, four or more LEDs are required (★2).

Click for the image.

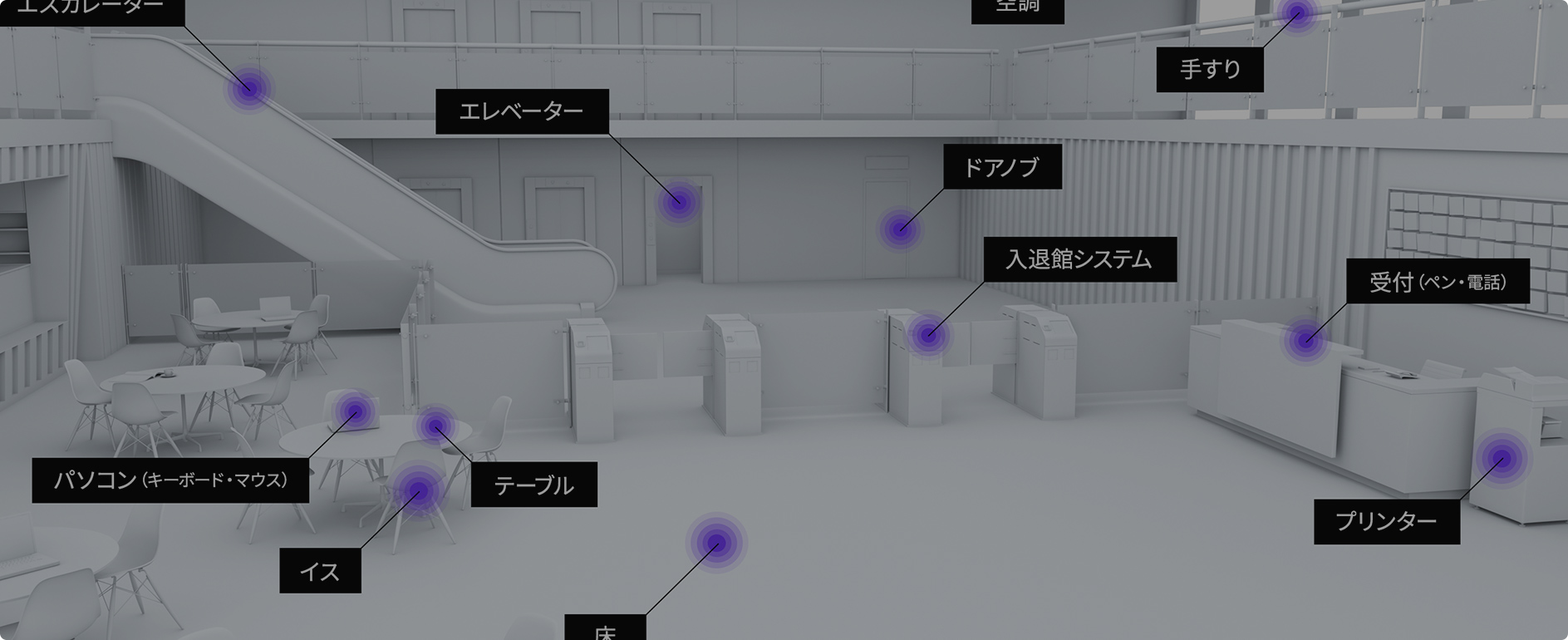

Applications with UV-C disinfection

-

How UV-C disinfect?

How UV-C disinfect? -

Stanley Electric's UV-C technology

Stanley Electric's UV-C technology -

Product lineup

Product lineup